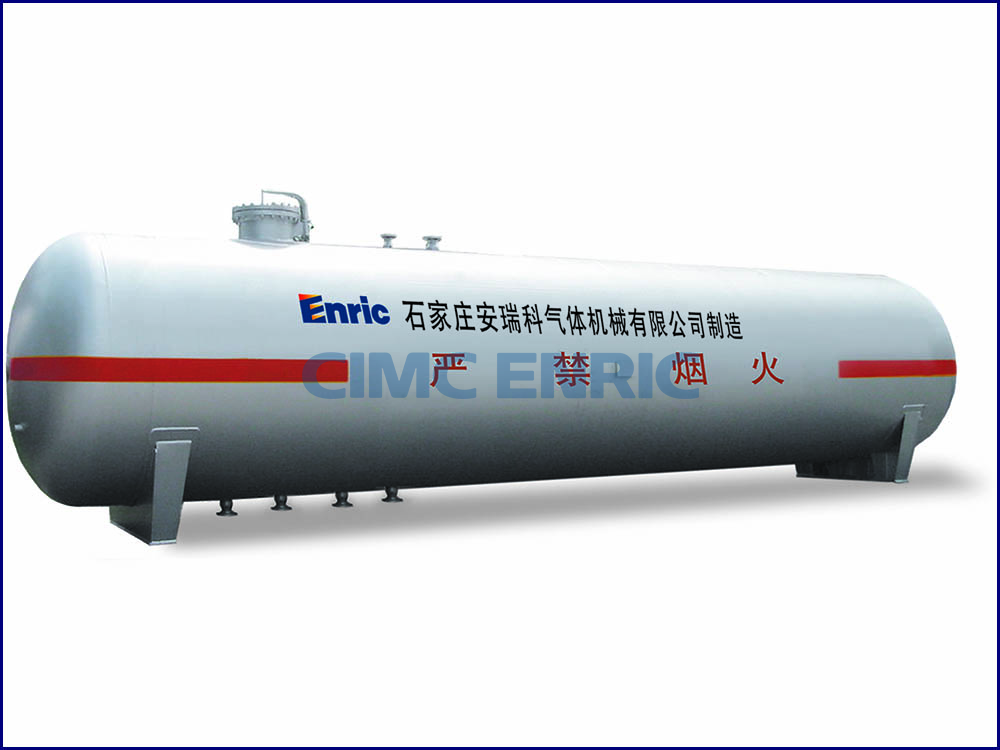

The LPG storage tank is a normal temperature fixed pressure vessel, a single-layer tank structure, dedicated to storing liquefied petroleum gas, using low-alloy steel plates for the vessel, with excellent performance, safety and reliability.

In order for LPG to liquefy, it must be subjected to specific cooling and pressure conditions, which must also be maintained during storage (and possibly transport) - this requires LPG storage tanks. LPG storage tanks are pressure vessels for storing liquefied petroleum gas (propane) as the main component medium. LPG storage tanks are one of the most efficient ways of storing liquefied LPG, with capacities ranging from 10 (2640gl) to 200 (52800GL) cubic metres. (1,000 gallon and larger tanks - these tanks are used for large residential applications (over 4,500 sq ft) or commercial and industrial applications - also known as CIMC ENRIC production.

CIMC ENRIC LPG Storage Tank ranges from determining the distance requirements for each tank to determining the right space conditions for storage. You should also consider whether you want to store them vertically or horizontally. Before handling or even distributing LPG storage tanks, you must first obtain approval from the regulatory authorities. They must ensure that the facility where you intend to store the tanks is large enough to accommodate the capacity you need. You must also have a minimum workforce to manage the facility in the event of a fire, on-site fire extinguishers, etc.

There are two basic types of above-ground propane LPG tanks: horizontal tanks and vertical tanks. Horizontal propane tanks (sometimes called "torpedo tanks") are large-capacity containers typically used where propane is the main source of heat in the home. Their increased storage capacity can limit the need for propane delivery in winter, which can help in areas where the weather is unpredictable.

CIMC ENRIC produces LPG storage tanks, mainly horizontal, for large commercial and industrial storage and transport.

CIMC ENRIC is a leading company in specialty gas storage and transportation equipment in China and can supply you with the best quality lpg tanks to meet the requirements of each country. We will guide you in your local compliance with storage regulations to ensure maximum product safety.

We have professional design and manufacturing qualifications of Chinese A2, A3, C2, SAD and American ASME U/ U2.

The main material is low-alloy steel plates for pressure vessels, the valve accessories are selected from famous brands in the industry, professional design and manufacturing team, perfect quality assurance system, the existing series volume from 10m³~400m³, can be customized according to customer needs.

This LPG Storage Tank is a special tank container (excluding external pipes) for storing liquefied petroleum gas. It can be equipped with special safety accessories and loading and unloading accessories according to customer needs.

Primary advantages

Safe and reliable, large volume, high loading capacity.

CIMC ENRIC has the design & fabrication capacity of LPG stationary storage tanks including above-ground tanks, underground tanks and mounded tanks etc. All kinds of tanks could be customized according to the customers' requirements.

Unique deliveries

EXW/FOB/CFR/CIF/DAP

Shipped by Bulk or Container vessel

Warranty information

One year warranty after delivery

Payment method

T/T,L/C

Main markets

Asia, Southeast Asia, Africa, South America , North America

Product specifications

Technical parameters

| I. Chinese GB Standard | |||||||

| Water Capacity | Inner Diameter | Overall Length | Height | Weight | Payload(90% Filling Ratio) | Thickness | |

| Shell | Heads | ||||||

| 10m³ | 1600mm | 5300mm | 2370mm | 3400kg | 4035kg | 8.53mm | 8.51mm |

| 12m³ | 1600mm | 6300mm | 2370mm | 3800kg | 4850kg | ||

| 20m³ | 2200mm | 5680mm | 2970mm | 5150kg | 8070kg | 11.35mm | 11.33mm |

| 25m³ | 2200mm | 7000mm | 2970mm | 6000kg | 10090kg | ||

| 32m³ | 2200mm | 8850mm | 2970mm | 7200kg | 12920kg | ||

| 40m³ | 2470mm | 8843mm | 3240mm | 8780kg | 16410kg | 12.62mm | 12.59mm |

| 50m³ | 2470mm | 10903mm | 3240mm | 10420kg | 20180kg | ||

| 63m³ | 2470mm | 13623mm | 3240mm | 12600kg | 25420kg | ||

| 80m³ | 3100mm | 11170mm | 3800mm | 16700kg | 32280kg | 15.58mm | 15.87mm |

| 100m³ | 3100mm | 13850mm | 3800mm | 20000kg | 40350kg | ||

| 150m³ | 3400mm | 17140mm | 4104mm | 29800kg | 60500kg | 17.35mm | 17.31mm |

| 200m³ | 3800mm | 18324mm | 4560mm | 40100kg | 80700kg | 19.27mm | 19.22mm |

| Main Material | Q345R | Design Pressure | 1.61MPa |

| Hydraulic Test Pressure | 2.22MPa | Working Pressure | ≤1.61MPa |

| Corrosion Allowance | 1.0mm | Design Temperature | -20/50℃ |

| Life Expectancy | 20 years | Working Temperature | -20/50℃ |

| Notes: Above existing design capacities for you to choose from. If you have any other different requirements, we could also provide you with customized design. | |||

| II. ASME Standard | |||||||

| Water Capacity | Inner Diameter | Overall Length | Height | Weight | Payload(85% Filling Ratio) | Thickness | |

| Shell | Heads | ||||||

| 10m³ | 1600mm | 5308mm | 2440mm | 3850kg | 4630kg | 11.09mm | 11.02mm |

| 12m³ | 1600mm | 6308mm | 2440mm | 4340kg | 5560kg | ||

| 20m³ | 2200mm | 5690mm | 3050mm | 6920kg | 9260kg | 14.86mm | 14.78mm |

| 25m³ | 2200mm | 7010mm | 3050mm | 8100kg | 11580kg | ||

| 32m³ | 2200mm | 8860mm | 3050mm | 9750kg | 14820kg | ||

| 40m³ | 2470mm | 8851mm | 3320mm | 11930kg | 18530kg | 16.56mm | 16.47mm |

| 50m³ | 2470mm | 10911mm | 3320mm | 15420kg | 25470kg | ||

| 60m³ | 2470mm | 13001mm | 3320mm | 16600kg | 27790kg | ||

| 80m³ | 3100mm | 11178mm | 3960mm | 22820kg | 37060kg | 20.53mm | 20.41mm |

| 100m³ | 3100mm | 13858mm | 3960mm | 27430kg | 46320kg | ||

| Main Material | SA-516 Gr.70 | Design Pressure | 1.724MPa |

| Hydraulic Test Pressure | 2.25MPa | Working Pressure | ≤1.724MPa |

| Corrosion Allowance | 1.0mm | Design Temperature | 50℃ |

| Specific Gravity | 0.545@15℃ | Working Temperature | -20/50℃ |

| Notes: Above existing design capacities for you to choose from. If you have any other different requirements, we could also provide you with customized design. | |||

Package included

Nude Packing

Accessories or Parts

Accessories or Parts will be packed in Steel or Wooden Cases if needed.

Why should I buy this product?

Forty years of professional design and manufacturing experience, reliable quality and service guarantee.

What makes this product different to competitor products?

High cost performance, quality assurance, high responsibility and perfect after-sales service system.

What benefits will you get from LPG Storage Tank?

Customers can safely store LPG with this tank.

Where can this LPG Storage Tank be used?

This LPG Storage Tank can be used in areas where the ambient temperature is -40℃~50℃.

Who might use this LPG Storage Tank?

LPG trading companies, gas station operators and large petrochemical companies are potential customers of this product.

Use range

It is suitable for mixing liquefied petroleum gas, propane, commercial propane, commercial propane butane mixture, propylene, anhydrous ammonia and other C4 mediums.

Some common uses of the LPG Storage Tank?

Long-term storage

When considering LPG tanks, a number of risks must be considered.

There is a risk of explosion

There is also a risk of asphyxiation due to LPG leaks

It is a highly flammable substance

In its liquefied state, contact with LPG can cause severe burns

How to choose a storage tank

Tank material selection: LPG storage tanks are manufactured from standard strength pressure vessel special steel plates because they need to meet low temperature and high pressure storage requirements

Quality control points in the process: advanced automatic ring welding equipment ensures stable weld joints and even and smooth surface joints to ensure the safety of LPG storage tanks

Valve fittings and flange selection: high quality and sealing of valve fittings such as well covers, safety valves, manual venting valves, thermometers and level gauges

Tank painting: tank sanding and rust removal, spraying anti-rust paint, hanging ion paint, and finally brushing primer and topcoat these steps. No paint loss and no fading is one of the conditions to test the durability

Emergency arrangements: The supplier's emergency telephone number will be printed on the LPG tank and should be dialled in the event of a leak.

When using LPG tanks, the following safety measures are recommended.

It is recommended that LPG bulk tanks are installed in well-ventilated or outdoor areas and at ground level. Mechanical ventilation systems should be considered to ensure that fresh air is provided.

LPG storage tanks must be protected from any source of ignition or heat and be fire rated. Combustible materials should also be kept away from LPG tanks, as well as anything that may generate static electricity.

These units should be kept away from incompatible substances and the use of barrier systems (e.g. screen walls made of non-combustible materials) should be considered.

The use of alarm systems and air quality testing to monitor potential LPG leaks is recommended.

When operating LPG tanks, staff must wear adequate personal protective equipment to avoid freezing burns and other hazards.

A proper maintenance schedule must be ensured to avoid tank bursts and other safety issues.

Pressure-reducing valves are a common accessory for LP gas cylinders. These can help relieve pressure to prevent pressure build-up from endangering the system.

The engineering team responsible for the design and implementation of LP gas tanks must comply with the required national and international legislation and quality protocols.

LPG tanks must be stored vertically with the valves closed. The use of appropriate restraint methods, including chains or safety belts, must also be considered.

These storage solutions must also maintain all necessary documentation documenting the safety measures taken, as well as all documentation relating to hazardous materials protocols.

Siting of the tank

There should be a minimum separation distance (called spacing distance) between the tank and any building, boundary line or fixed source of ignition. This should have been checked when the tank was installed, if you are not sure, please consult us and we will help you with the installation plan and service.

Ventilation and surroundings of the tank: In the event of a leak, there should be enough space around the tank to allow sufficient air movement so that heavier-than-air LPG vapour does not form.

Shock protection: If possible, the tank (and its accompanying pipework) should be placed away from areas of high pedestrian traffic. If this is not possible, protection from motor vehicle impact on the tank is required, e.g. crash barriers or bollards.

CIMC Enric LPG Storage Tank

CIMC Enric - A leading supplier and manufacturer of storage and process containers, specializing in NGL and LPG/propane, butane and anhydrous ammonia/NH3 bullet tanks and associated equipment. We also offer the most comprehensive range of related equipment including LPG and NH3 pumps, compressors, valves, liquid transfer and metering systems, evaporators, mixing systems and much more. If you can't find the tank or equipment you're looking for, we'll find it for you - and deliver it at a competitive price. We also offer storage solutions for LPG (liquefied petroleum gas), propane, butane, pentane, ammonia, anhydrous ammonia and other gaseous products. We have the experience, capability and flexibility to provide a reliable solution for your customized storage container application.

CIMC ENRIC designs and manufactures storage tanks for all phases of oil and gas processing and production. We offer ASME certified storage solutions for LPG (propane), LNG (methane), NGL (including ethane, propane, butane, pentane and isobutane) and other gaseous products, with custom tanks and pressurised vessels ranging in capacity (up to 50,000 gallons).

We are a self-performing, turnkey solution provider for LPG storage tanks, manufactured to your exact specifications and to the highest quality standards. All work, including assembly, welding, painting and coating, is carried out by skilled craftsmen. We handle and perform all aspects and services associated with LPG, LNG and NGL tank fabrication projects while following strict quality controls in design, materials, fabrication, welding, inspection and testing. We assist you in equipping your premises with LPG tanks, dispensing equipment and the necessary hardware to comply with gas pumping and dispensing equipment regulations. We are obsessed with quality. We source commercial gas pumps and dispensing equipment for high volume applications from associated European and American companies, and our LPG tanks and dispensing equipment for high volume applications are designed to meet European standards.

CIMC ENRIC offers skid-mounted, modular storage and pressurised tank systems for all your storage vessel needs with cost and time saving benefits. We can design, engineer, manufacture and install your next LPG storage tank as an addition to an existing processing plant or as part of a fully integrated, modular oil and gas processing plant or refinery.